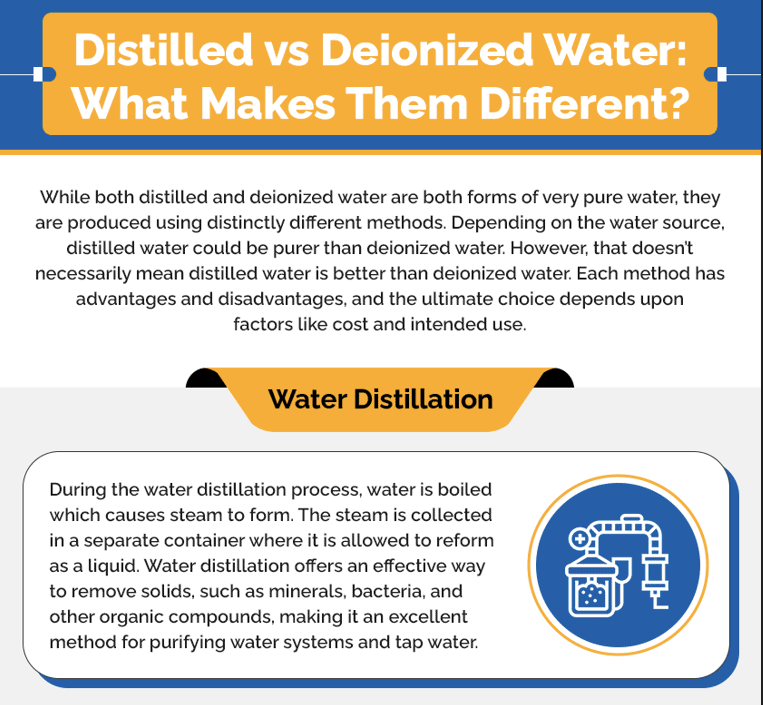

Distilled vs Deionized Water: What Makes Them Different?

Leave a CommentWhile both distilled and deionized water are both forms of very pure water, they are produced using distinctly different methods. Depending on the water source, distilled water could be purer than deionized water. However, that doesn’t necessarily mean distilled water is better than deionized water. Each method has advantages and disadvantages, and the ultimate choice depends upon factors like cost and intended use.

Water Distillation

During the water distillation process, water is boiled which causes steam to form. The steam is collected in a separate container where it is allowed to reform as a liquid. Water distillation offers an effective way to remove solids, such as minerals, bacteria, and other organic compounds, making it an excellent method for purifying water systems and tap water.

Distilled water is the most common form of purified water and is often confused with deionized water. While both forms of water are safe to drink, deionized water is the purest of the two. However, distilled water is capable of conducting electricity, making it ideal for applications such as laboratory experiments. Its purity also makes it suitable for sterilizing medical equipment and for use in cosmetic products.

Water Deionization

Water deionization involves an ion exchange process that works to remove solid materials from water. During the process, untreated water flows through two oppositely charged resin beds. As this occurs, electrically charged ions are removed, leaving only hydrogen and oxygen molecules behind. The result is highly purified water that is ideal for applications requiring extreme water purity, such as automotive, pharmaceutical, biochemistry, immersion cooling, and more.

Deionized water does not contain charged ions, meaning it is resistant to electricity. This makes it the preferred form of water in many instances. For example, many machining and other processes involving high temperatures benefit from deionized water’s low electrical conductivity, as it helps to lower temperatures during manufacturing.

Water deionization offers an effective, cost-efficient, and consistent method for purifying water systems.

Effective, Safe Water Treatment From Reynolds Culligan

We understand that it is not always easy to get quick answers when researching water purification systems. With a vast amount of information on the internet, it can be overwhelming to know where to start. Hopefully, you now have the essential information to understand the distinctions between distilled and deionized water to help you determine which method may be right for your needs.

Since 1948, Reynolds Culligan has been the only water treatment company in the Mid Atlantic that offers a comprehensive, single-source water treatment technology platform that works for virtually any industry and application. We are proud to offer cost-effective solutions for residential, commercial, and industrial applications, with a modular platform that allows our customers to customize our solutions to their specific needs.

Our team has over 200 years of combined experience serving diverse industries such as:

- Educational Facilities

- Energy & Power

- Food & Beverage

- Healthcare & Pharmaceuticals

- Hospitality & Lodging

- Manufacturing

- Municipal Water Treatment

- Wastewater Treatment

To learn more about Reynolds Culligan and our water purification systems, please contact us today.

The Differences Between Coagulation and Flocculation in Water Treatment

Leave a CommentCoagulation and flocculation are two methods used to increase particle size and enhance filtration efficiency. Regardless of the size of the system, coagulation and flocculation are typically the initial steps in water and wastewater treatment.

At their most basic, coagulation and flocculation involve the process of adding positively charged chemicals to the water. These chemicals neutralize negatively charged dirt and other dissolved particles in the water, which causes them to bind with the chemicals to form larger, more easily filtered particles, called floc. Although both processes have the same end goal and are often used together, there are fundamental differences between the two.

Coagulation

Coagulation in water treatment uses specialized chemicals to encourage fine particles to clump together. These chemicals, known as coagulants, create an electronic charge that causes the particles to cluster into larger groupings that make them easier to filter.

Types of Coagulants

Coagulants used in water filtration applications are typically either aluminum or iron-based.

Common aluminum coagulants include:

- Aluminum sulfate

- Aluminum chloride

- Sodium aluminate

Common iron-based coagulants include:

- Ferrous sulfate

- Ferric sulfate

- Ferric chloride

- Ferric chloride sulfate

In addition to the above, water filtration facilities may also use hydrated lime and magnesium carbonate.

Coagulation Process

The coagulation process uses coagulant chemicals to destabilize negatively charged particles in the water, such as dirt, clay, soil, and other organic particles. Since the negative charge is what keeps these dispersed particles from coalescing, neutralizing that charge allows those solids to stick together, creating submicroscopic clumps of particles known as microflocs.

To facilitate the collision of particles for optimal coagulation, the liquid must be mixed rapidly. This quickly disperses the coagulant into the water, while facilitating the formation of clumps by forcing more of the neutralized particles to collide. To ensure optimal coagulation, it is recommended that the water be agitated at high speed for 1-3 minutes after the coagulant has been added. Once the coagulation process is complete, the water is often treated using flocculation.

Flocculation

While coagulation helps to encourage particles to combine into larger, more easily filtered clumps, the resultant microflocs are still far too small for standard filtration systems to clear. Flocculation takes the coagulation process a step further by gently agitating the microfloc-containing water at varying speeds to encourage more particle adhesion.

Flocculation Process

The flocculation process takes treated water from the coagulation stage and mixes it slowly to increase the collision rate between suspended microfloc particles. As they collide, the microflocs bond further to create larger flocs, which are visible to the naked eye.

Through additional mixing, these flocs continue to grow and bond with other organic or inorganic polymers which may be produced by the coagulant or coagulant aids added during this step. With these polymers, the flocs form into macroflocs, which become increasingly heavy. The added weight allows the macroflocs to settle at the bottom, where they can be easily removed.

Flocculation Variants

The amount of flocculation induced during the mixing process differs based on the mixing speed and the amount of time for which the material is mixed. There are a variety of mechanisms used to control flocculation speed and particle aggregation to produce the desired particle size and consistency. While rotating blades are the most common flocculation equipment for large-scale water treatment facilities, other methods include granular media beds, diffused air, baffled chambers, and spiral flow chambers.

Expert Water Treatment by Reynolds Culligan

Since 1948, Reynolds Culligan has been the only Mid Atlantic industrial water treatment provider who offers single-source, comprehensive water treatment solutions for virtually every industry. To learn more about our extensive selection of water treatment technology systems for industrial, commercial, and residential applications, contact Reynolds Culligan today.