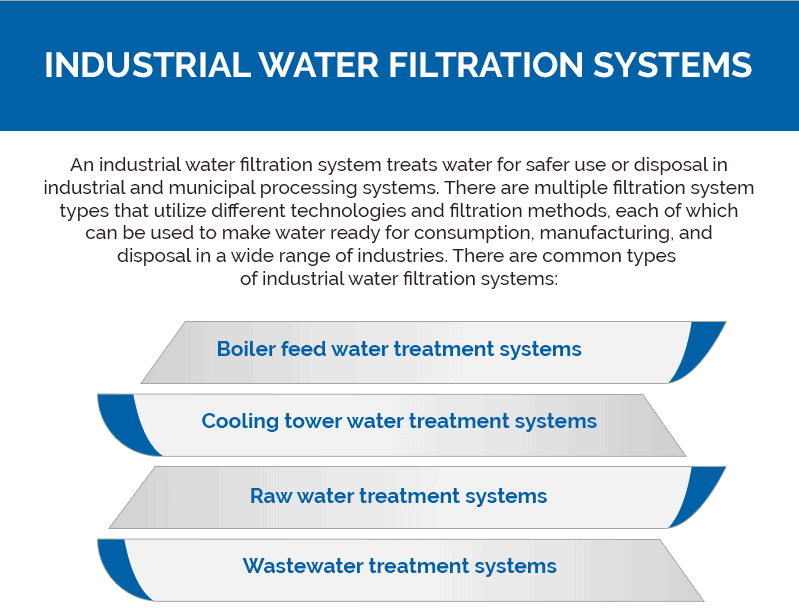

Industrial Water Filtration Systems

An industrial water filtration system treats water for safer use or disposal in industrial and municipal processing systems. There are multiple filtration system types that utilize different technologies and filtration methods, each of which can be used to make water ready for consumption, manufacturing, and disposal in a wide range of industries. There are common types of industrial water filtration systems:

- Boiler feed water treatment systems

- Cooling tower water treatment systems

- Raw water treatment systems

- Wastewater treatment systems

How Does an Industrial Water Filtration System Work?

Raw water is untreated and must undergo a series of filtration and treatment steps to make it safe for consumption or industrial use. Raw water may come from a variety of sources, such as rainwater, bodies of water, and groundwater. Treating water doesn’t just make it safe for human contact or consumption. Removing impurities, pathogens, and minerals can also help preserve a facility’s systems. For example, softening hard water removes calcium and magnesium that could otherwise start to build up in pipe joints and around valves.

Every industrial water filtration system is slightly different, customized to the unique needs of the facility and the unique demands of the area’s raw water. However, most industrial water filtration systems follow a basic five-step process to filter water and make it safe for use:

1. Intake

First, the water filtration system brings in raw, or untreated, water. It uses either gravity or pumps (or a system with both methods) to draw the water in. The intake system also has a grate that blocks large objects from being taken into the system.

2. Clarification

To remove more solids from the raw water, the water is sent through the clarification process. Clarifying involves multiple stages, including coagulation. Coagulation adds chemicals and adjusts the water’s pH levels to make solids clump together for easier filtration.

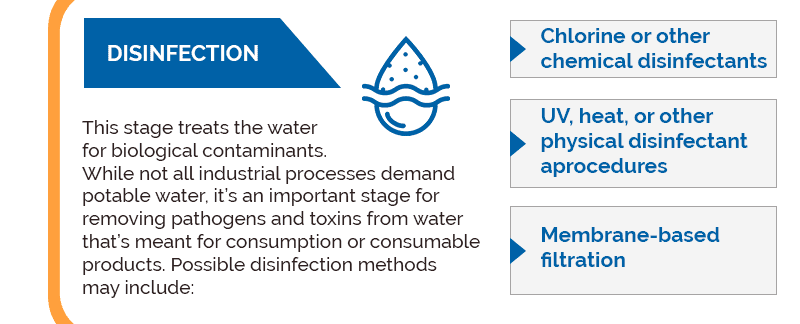

3. Disinfection

This stage treats the water for biological contaminants. While not all industrial processes demand potable water, it’s an important stage for removing pathogens and toxins from water that’s meant for consumption or consumable products. Possible disinfection methods may include:

- Chlorine or other chemical disinfectants

- UV, heat, or other physical disinfectant procedures

- Membrane-based filtration

Membrane filtration can also take place later in the filtration cycle. It uses microfiltration, ultrafiltration, or nanofiltration to filter water on an increasingly fine scale.

4. Ion Exchange (IX)

Ion exchange units can soften water and provide other specialized treatment functions. To soften hard water, an IX unit sends streams of water through an acid cation resin. The resin is charged with sodium, which lets it capture calcium and magnesium.

5. Distribution

The distribution system within the industrial water filtration system routes the treated water into a facility’s systems for manufacturing use or consumption or off-site for disposal.

Benefits of Industrial Water Filtration Systems

Industrial water filtration systems give industrial facilities the ability to treat their own water. Not only is this a requirement for many municipalities but having an onsite water filtration system gives companies access to several benefits. These include:

Increased Efficiency

Being able to cleanse and filter water lets facilities reuse contaminated water. They can also spend less on raw water and be less dependent on local municipal systems for meeting their water needs. Facilities in areas with droughts, water restrictions, and high levels of competition for water can maintain consistent production and processing cycles with fewer shutdowns and uncertainties. An onsite filtration system also allows facilities to tailor their filtration process to suit their needs.

Increased Sustainability

Increased population, consumption, and industrial manufacturing puts a strain on an area’s natural water tables and access to raw water. Pollution, climate change, and insufficient infrastructure can also contaminate water and make it unfit for use. The more facilities can filter and reuse their own water, the better. Having an onsite filtration system also gives facilities more flexibility when choosing their water sources because they have the ability to sufficiently treat it for use. Companies can save money and reduce overall raw water demand.

Low Energy Consumption

Modern filtration systems are increasingly energy-efficient. Facilities can customize their filtration systems to run at off-peak hours; use energy-efficient clarification, disinfection, and ion exchange processes; and monitor energy use.

Low Maintenance Costs

Smarter, more modern industrial water filtration systems also cost less to operate and maintain. The systems are built for long lifespans and can be regularly replenished instead of entirely replaced. With Reynolds Culligan, facilities can have regular replenishment of resins and chemical treatment solutions.

Industrial Water Filtration Systems from Reynolds Culligan

At Reynolds Culligan, we specialize in turnkey solutions for commercial, industrial, and municipal water filtration system needs. Since 1948, we’re the only company in the Mid-Atlantic region to offer a comprehensive solution. Our single-source technology platform makes it easy for facilities to filter water in-house and efficiently meet their water demands.

With the entire Culligan International organization behind us, Reynolds Culligan provides simple, comprehensive water filtration on any scale. Contact us today to learn more about our capabilities.