Water Treatment Services

Reynolds Culligan is the only industrial and commercial water treatment services company in the Mid-Atlantic who provides a single-source, comprehensive water treatment technology platform for virtually any industry and application. This quality allows us to save your business valuable time and resources.

With over 70 years of combined industry experience, competitive prices, and professional after-sale services, you can be confident that we provide exceptional products, service, and follow-up.

What Are Water Treatment Services?

Water treatment services improve water by bringing it to operation-appropriate standards for industrial and consumer applications, such as drinking, chemical processing, irrigation, and recreational water activities. Generally, treatment processes focus on reducing or removing unwanted chemicals and contaminants, such as minerals and microorganisms.

At Reynolds Culligan, we provide the following water treatment services:

Deionization

The deionization process employs specialized ion exchange resins to physically bind to and remove mineral salts from water. Industry professionals use the process to produce higher quality water by removing mineral cations and anions, such as those from calcium, copper, iron, and sodium and bromide and chloride, respectively.

Our deionization water treatment solutions allow us to produce the following types of water:

- High-purity water. High-purity water—also referred to as ultrapure or highly purified water—is water treated to meet the strictest purity and quality standards. By employing a three-stage treatment process—i.e., pretreatment, primary purification, and polishing—industry professionals can strip the water of all types of chemicals and contaminants, including organic and inorganic, solid and fluid, and reactive and inert compounds.

- Deionized/demineralized water. Deionized water—also known as demineralized water—is water that been treated specifically to remove mineral ions such as those from dissolved salts. Compared to high-purity water, it may still contain organic particles and non-mineral compounds.

- Lab-grade and medical-grade water. Lab-grade and medical-grade water is a form of high-purity water that meets the purity and quality standards for use in laboratory and medical applications. These standards are set forth by a variety of regulatory bodies, such as the US Pharmacopeia (USP), Clinical and Laboratory Standards (CLSI) Institute, and College of American Pathologists (CAP).

Water Softening

Similar to the deionization process, the water softening process employs ion exchange to remove minerals such as calcium and magnesium that contribute to the creation of “hard water”. When used in industrial, commercial, and residential systems, hard water can leave behind calcium deposits, limescale, and other mineral traces that can build up and damage appliances and other equipment.

The use of water softeners benefits a wide range of industrial and commercial markets by extending the service life of their fluid handling equipment, including the following:

- Educational Facilities

- Energy and power

- Food and beverage

- Hospitality and lodging

- Industrial manufacturing

Reverse Osmosis

Reverse osmosis is a water treatment method that utilizes a partially permeable membrane and pressure to remove ions and larger contaminants from water. The application of pressure allows the unprocessed water to overcome osmotic pressure and separate into the pure solvent (clean water) and solute (the contaminants). Although reverse osmosis and filtration have some similarities, they employ distinctly different removal mechanisms; reverse osmosis uses osmosis across a membrane, while filtration uses exclusion by size.

When used in industrial applications, reverse osmosis systems provide several benefits, including:

- Greater aesthetics. Reverse osmosis-treated water can leave a cleaner, spot-free finish in car washes and create clearer ice cubes for use in restaurants.

- Higher cost-effectiveness. Compared to other water treatment processes, reverse osmosis is one of the most affordable methods per gallon.

- Better taste. Reverse osmosis removes mineral contaminants that could otherwise affect the taste of consumable goods, such as soups, stews, and beverages.

Dealkalization

The alkalinity of water relies on the presence of compounds such as hydroxide, carbonate, and bicarbonate, all of which are pH-dependent. High-alkalinity water, when heated, can develop corrosive characteristics that cause damage to equipment and systems. Dealkalization is a water treatment process that uses chloride form anion resins to facilitate ion exchange, reducing the alkalinity of the processed water.

Employing dealkalization equipment—i.e., dealkalizers—has several benefits, such as:

- Preventing corrosion and hard water scaling development in equipment

- Reducing the need for repairs and replacements and lowering related costs

- Extending the overall service lives of systems

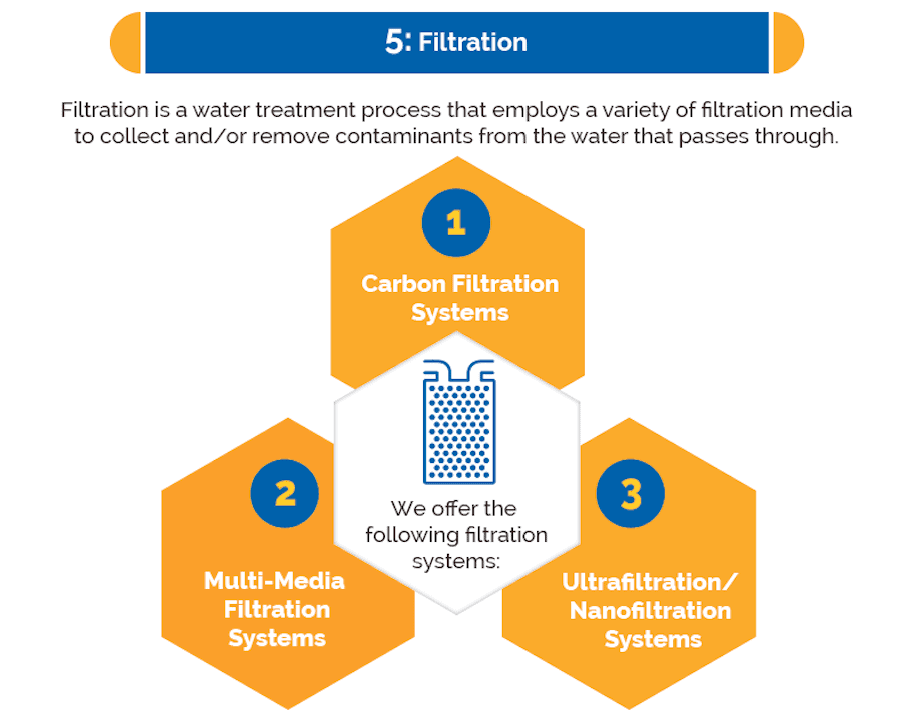

Filtration

Filtration is a water treatment process that employs a variety of filtration media, such as carbon, sediment, and semi-permeable membranes, to physically collect and/or remove contaminants—particularly solids and large particulates—from the water that passes through. Some of the industrial and commercial markets that employ filtration systems are:

- Car washes

- Educational facilities

- Energy and power

- Food and beverage

- Health care

- Hospitality and lodging

- Industrial manufacturing

- Pharmaceuticals

The types of compounds removed from the water depend on the type of filtration system employed. At Reynolds Culligan, we offer the following types of filtration systems:

Carbon Filtration Systems

Industry professionals often use carbon filtration systems for the removal of compounds that can affect the taste, color, and odor of water and water-based substances, such as chlorine. These systems utilize a variety of carbon filtration media to absorb volatile organic carbons (VOCs), small particulates, and other halogens. Certain carbon variations also allow for the absorption of lead and other heavy metals.

Multi-Media Filtration Systems

Multi-media filters use several types of filtration media of various sizes to filter out different solid contaminants from water. The use of larger-sized media removes larger compounds, and successively finer media removes smaller compounds.

At Reynolds Culligan, multi-media filters are one of our specialties. We produce filtration systems that use three to four types of media to suit the needs of a wide range of industrial and commercial applications.

Ultrafiltration/Nanofiltration Systems

Ultrafiltration and nanofiltration systems employ semi-permeable membranes to remove very small suspended solids from water. The distinction between the two lies in the pore size of the membrane:

- Ultrafiltration membranes have pore sizes that are larger than those of nanofiltration and reverse osmosis membranes but smaller than microfiltration membranes. They are not capable of reducing or removing ions from water.

- Nanofiltration membranes have pore sizes that are larger than reverse osmosis membranes but smaller than both ultrafiltration and microfiltration membranes. They are capable of removing 50–90% of dissolved ions from water.

Ultraviolet Disinfection

Ultraviolet disinfection is a water treatment process that sterilizes and disinfects incoming water to make it safe for consumption and sensitive manufacturing or testing operations. Often used alongside other filtration and treatment methods, the process employs ultraviolet (UV) light to destroy up to 99.99% of microorganisms, such as E.coli or giardia, in the water that can cause illness or affect the quality of products submerged in or producing using it.

Some of the key benefits of UV disinfection include:

- It is highly effective at eliminating the presence of pathogens in water.

- It doesn’t require the use of chemicals.

- It doesn’t impact the taste, smell, or color of the water.

- It has low energy use and maintenance requirements.

- It can help facilities meet AAMI, ASTM, CAAP, and MCCLS water standards.

Water Treatment Services From Reynolds Culligan

Employing water treatment systems in your facility can help protect your employees and customers and improve the quality and integrity of your products by removing undesirable compounds and contaminants.

At Reynolds Culligan, we provide comprehensive water treatment solutions that can be completely customized to fit your facility’s needs. If you need industrial water treatment, we can help. Our professional services include:

- Biological control/sanitization

- Chemical treatment

- Engineering/system design

- Equipment sales, rental, and leasing

- Portable exchange deionization (DI)

- Preventative maintenance contracts

- Repair/replacement parts

- Resin/media analysis and re-bedding

- Salt delivery (automatic, periodic, or on-call)

- Service agreements

- Start-up of equipment and/or systems

Contact our team today to learn more about our water treatment solutions and how they can benefit your company.